INDUSTRIAL FLUID CLEANLINESS SERVICES

About

Design It Clean, Built It Clean, Maintain It Clean

Industrial Fluid Cleanliness Services, Specialist Hydrocarbon Best Practices.

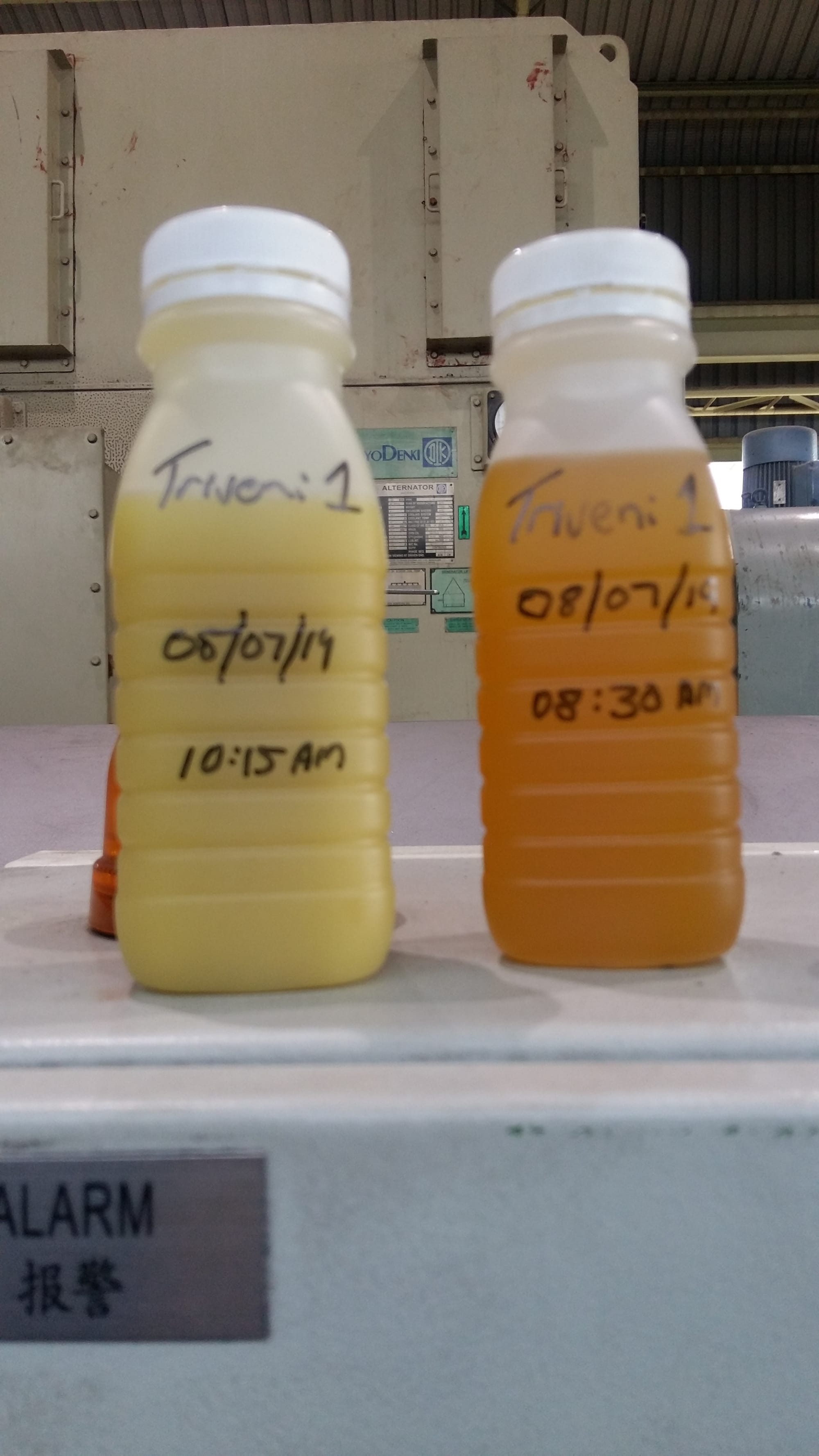

Transformer oil purification. On-Line On-Load, Off-Line Off-Load.

- Lubrication and Hydraulic Fluid

- Storage,

- Transfer,

- Maintenance and

- Disposal.

- Preventing failures through Measure, Monitor, Manage.

- Filtration.

- Purification.

- Transformer Oil Purification.

- Varnish mitigation.

- Remote monitoring.

- Visual inspection.

- Sample valves Low pressure High Viscosity, High pressure Low viscosity .

- Training.

Transformer oil purification. On-Line On-Load, Off-Line Off-Load.

Services

Monitor

Fluid Cleanliness Monitor. Oil sampling valves and probes. Visual oil monitoring equipment.

Learn More

Manage

Desiccant Breathers. Filters and Filter Housings. Transfer carts. Purification equipment.

Learn MoreContact

- 20 Viljoen Crescent, Randpoort, Randfontein, 1759, Gauteng, South Africa

Oil and Diesel Cleanliness, Water removal, Monitoring, Filters, Breathers.